how to test the hardness of a material|types of hardness tester : custom The hardness test developed by Friedrich Mohs was the first known test to assess resistance of a material to scratching. It is a very simple but inexact comparative test. Perhaps its simplicity has enabled it to become the most .

webFreteBras | Encontre mais de 45.000 fretes para transportar pelo Brasil. Fretes Para .

{plog:ftitle_list}

Um número sozinho não pode ser rastreado em outro disposi.

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as .

h20 beauty moisture meter

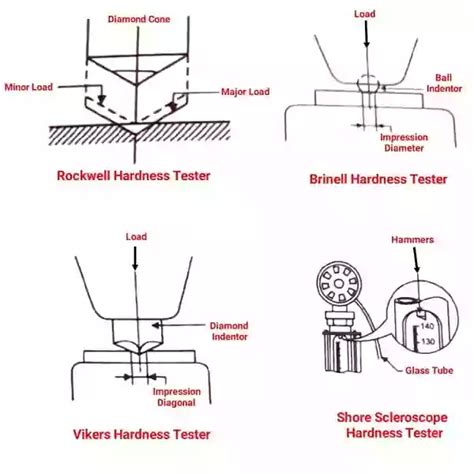

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most .It’s most commonly used to check the hardness of steel that’s been heat treated. Here’s the process: How to Use a Rockwell Testing Machine. Pick out the .There are two principal methods of testing the hardness of a material – scratch testing and indentation testing. Indentation testing can only be used on materials that undergo plastic .

types of material hardness

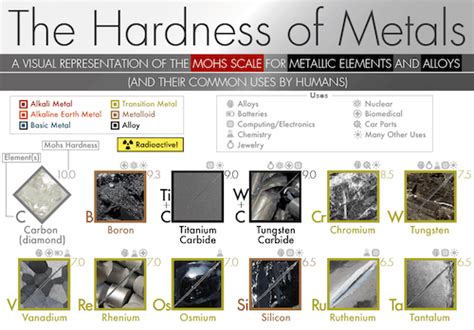

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals .The hardness test developed by Friedrich Mohs was the first known test to assess resistance of a material to scratching. It is a very simple but inexact comparative test. Perhaps its simplicity has enabled it to become the most .

Vickers Hardness Test. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness . Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to . The Mohs hardness test uses ten reference materials with different hardness. The kind of material under test determines the kind of reference to use. The result is then obtained by assigning a numerical hardness value to the test material. Talk is the softest material used, with a value of 1. Brinell Hardness Test (ASTM E10) Rockwell (ASTM E18) Vickers; Knoop ; Brinell v Rockwell Hardness Test Hardness Test Characteristics General characteristics of hardness-testing methods and formulas for calculating hardness. Hardness Scale. The chart below is used for converting various hardness scales. Since all the hardness test are limited in .

types of hardness testing methods

types of hardness tester

Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).

Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5)

Hardness testing assesses a material's ability to resist permanent deformation at its surface by applying pressure with a harder material. . ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials. ISO 6508: This standard is very similar to ASTM E18, as it deals with the Rockwell hardness tests, .

Vickers is a hardness test for all solid materials, including metallic materials. The Vickers Hardness (HV) is calculated by measuring the diagonal lengths of an indent in the sample material left by introducing a diamond pyramid indenter with a given load. The diagonals of the indent are measured optically in order to determine the hardness .Hardness is dependent on ductility, elastic stiffness, plasticity, strain, strength, toughness, viscoelasticity, and viscosity. Common examples of hard matter are ceramics, concrete, certain metals, and super hard materials, which can be contrasted with soft matter. It involves scratching a material surface with reference materials of known hardness (e.g., minerals) and comparing the scratch patterns to determine the relative hardness of the material. While less precise than other hardness testing methods, the Mohs scale is useful for quickly assessing the hardness of minerals and geological specimens. Determining material hardness by measuring the diameter of the resulting indentations using a carbide ball or hardened steel is known as Brinell hardness test. For example, a ball approximately 10 mm in diameter is pressed into the surface of the material under an applied load commonly equal to 3,000 kgf for steels and 500 kgf for softer materials.

Rockwell hardness test is a fast testing method found for production control, with direct reading, used primarily for metallic materials. Rockwell hardness (HR) is calculated by measuring the depth of the indentation after inserting the indenter into the sample material at a given load, which reflects the measured resistance of the metal to indentation. Mohs Hardness is more like a comparative hardness test where the material is compared for indentation against a known material or hardness value. 10 minerals are ranked on the Mohs scale from low hardness to high hardness from 1 to 10 as shown in the below picture. .

Knoop Hardness Test: The Knoop hardness testing measures the hardness of small and delicate materials, thin sections, and coatings. These test methods employ a rhombic-based diamond probe. The elongated shape .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness testing is used for two general characterizations 1.Material Characteristics • Test to check material • Test hardenability • Test to confirm process • Can be used to predict Tensile strength .

Various hardness tests, from the Knoop hardness test to the Leeb hardness value, provide valuable insights into a material’s performance characteristics. Whether it’s the hardness measurement of a hollow vertical glass tube or the Brinell test for a metal surface, understanding hardness is vital to materials science. How to Test Material Hardness? Material hardness testing involves various methods, each shedding light on a material’s resistance to deformation. Here’s a guide to some common hardness tests: The Brinell Test: The Brinell hardness test involves pressing a spherical indenter into the material’s surface under a specific load. Rockwell hardness is determined by measuring the distance traveled by an indenter when a heavy load is applied to a heat treated part. Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part.

In the American metal material standards, a prominent feature regarding hardness testing is the preference for the Rockwell hardness test, supplemented by the Brinell hardness test, and seldom using the Vickers hardness test. The American view is that the Vickers hardness test should mainly be used for metal research and testing of thin, small .

how to measure surface hardness

Under the ISO/TS 19278:2019 standard, a hardness tester conforming to ISO 14577-1 (Metallic Materials – Instrumented indentation test for hardness and materials parameters – Part 1: Test method) is needed. In the Brinell hardness test, the test material is indented by use of a 10-mm-diameter hardened- steel/carbide ball that is subjected to a specified load, F (see Fig. 3.6). For hard materials, the full load of 3000 kgf is applied; whereas for softer materials, the applied load is in the range of 500–1500 kgf. The full load is normally applied .Manufacturers commonly measure material hardness and other properties for construction and other purposes. Types of Hardness Tests. You can determine the hardness of a material through a variety of tests. The four main tests are the Rockwell Hardness Test, the Vickers Hardness Test, the Knoop Hardness Test, and the Brinell Hardness Test. Understanding the idea of a material’s hardness and how to test it for hardness is a key part of the complicated field of material science. With a long past and a nature that is always changing, hardness testing has become an important way to judge the quality and suitability of materials in many industries.

The hardness of a material can be defined as, ‘the ability of a material to resist scratching, wear and tear and indentation’. Using a centre punch to ‘indent’ the surface of a material, is a basic test. Different materials require a different amount of force to form an indent. This makes it possible to compare the hardness of a .

Hardness is the resistance of a material to localized deformation or scratching. It’s a critical property for materials used in wear-resistant applications like cutting tools or bearings. Measurement. Hardness is measured using various methods, such as the Brinell, Rockwell, or Vickers tests.

hardness tester information

webUma canção cristã sobre a presença de Deus na vida de Davi, que é um personagem bíblico. A letra expressa admiração, gratidão e esperança por a presença de Deus na .

how to test the hardness of a material|types of hardness tester